Top Industries That Rely on Filter Sleeve Cages for Air Filtration

When we think about clean air – we usually picture fresh outdoor air or a well-ventilated indoor space. But in industrial settings – achieving clean air is far more complicated.

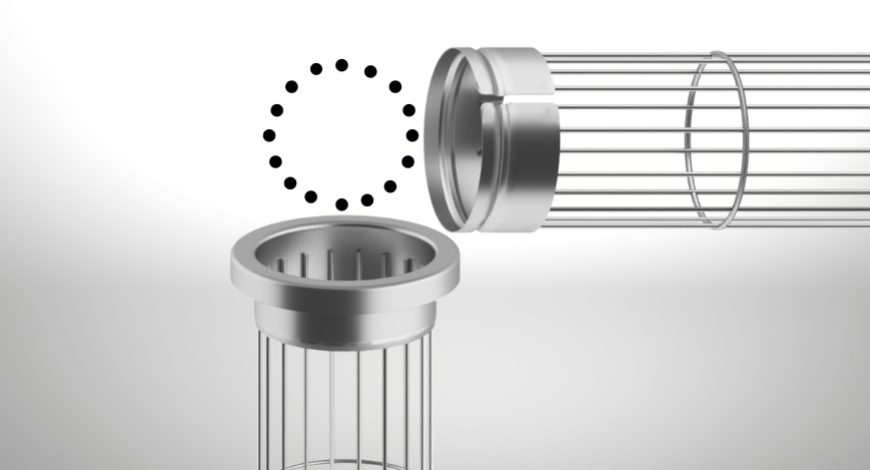

Industries rely on advanced systems to manage – dust, fumes, and particles that can harm the environment or workers. One such system involves filter sleeve holders cages for air filtration.

They provide support for filter sleeves – guaranteeing that air filtration systems function efficiently. Without them, many industries would struggle to maintain safe working conditions or meet environmental standards.

Did you know? The industrial air filtration market is valued at $8.2 billion in 2024 and is expected to grow to $19.2 billion by 2037.

In this blog – I will share the top industries that rely heavily on these systems and explain why they are so important.

The food industry

The food industry might not seem like a place for heavy-duty equipment – but it uses filter sleeve holders more than you’d think. In food production – dust from flour, sugar, grains, and other dry ingredients can become airborne. If not controlled – this dust can cause cross-contamination or even explosions.

Air filtration systems with robust filter sleeves and cages help trap dust particles – keeping the environment clean and safe. They also guarantee that food products remain uncontaminated. This helps to meet the health and safety regulations. In addition – these systems can improve the efficiency of production lines by minimizing the risk of equipment malfunction caused by dust accumulation.

Cement plants

Cement plants are among the dustiest places imaginable. The process of – crushing, grinding, and blending materials generates enormous amounts of fine dust. This isn’t just messy—it is hazardous to both workers’ health and machinery.

Filter sleeve cages are essential in these facilities. They support the filtration process by holding filter sleeves in place – allowing the system to trap fine particles effectively. Without proper air filtration – cement plants could pose serious risks to workers and the surrounding environment. Moreover, regulatory compliance would be nearly impossible without these systems – as emissions need to be tightly controlled.

Steel mills

Steel mills produce high levels of airborne contaminants, including – fine dust and toxic fumes from melting and forging metals. Air quality in these environments is critical – not just for worker health but also for operational efficiency.

Cages are integral to air filtration systems in steel mills. They handle the high-temperature demands and make sure that the filters perform effectively – capturing harmful particles and maintaining cleaner air in these challenging conditions. Their durability and reliability make them an indispensable component in keeping steel production safe and efficient.

Power plants

Power plants, especially those burning coal or biomass – generate significant levels of pollutants. Fly ash, soot, and other fine particles need to be controlled to prevent air pollution and meet environmental regulations.

This is where filter sleeve holders and advanced air filtration systems can help. They trap particulate matter – guaranteeing that emissions meet legal standards while reducing the plant’s environmental impact. Additionally, these systems contribute to better efficiency by maintaining cleaner boilers and turbines. It helps to reduce maintenance needs and extends equipment life.

Chemical manufacturing

Chemical plants work with a wide range of substances – many of which can produce harmful fumes and particles. Proper air filtration is non-negotiable in these facilities to protect workers and prevent chemical exposure.

Filter sleeve holders provide the backbone for filtration systems in chemical plants. They support filters that capture dangerous particles and fumes – keeping the air clean and reducing risks. This also ensures compliance with stringent environmental and safety regulations that govern the chemical industry.

Waste to energy plants

Waste-to-energy plants convert garbage into usable energy – but the process can release harmful pollutants. Dioxins, ash, and other emissions must be filtered to keep the environment safe.

In these plants – cages play a vital role in air filtration systems. They help trap fine particles and guarantee that emissions are controlled – making waste-to-energy plants more sustainable and eco-friendly. This not only benefits the environment but also boosts public perception of the facility’s operations.

Pharmaceutical manufacturing

Pharmaceutical facilities produce medicines – but they also generate dust and particles that need strict control. Clean air is essential in these environments to ensure product safety and worker health.

By using filter sleeve holders – filtration systems can handle the job effectively. These components keep filters in place – allowing the system to trap contaminants and maintain a clean production space. This helps pharmaceutical companies meet stringent hygiene and safety standards while protecting their workforce from airborne contaminants.

Mining industry

Mining operations involve crushing, drilling, and transporting materials, all of which generate massive amounts of dust. This dust can harm workers’ lungs and contaminate nearby areas if not properly managed.

Robust air filtration systems equipped with filter sleeve cages are critical in mines. They trap dust particles, improve air quality, and help miners work in safer conditions. Additionally, these systems protect the expensive machinery used in mining operations by preventing dust from clogging equipment – reducing downtime and repair costs.

Woodworking facilities

Whether it is furniture production or sawmills, woodworking creates a lot of sawdust. This sawdust can become a health hazard and even increase the risk of fire if left unchecked.

To manage this – filter sleeve cages are used in air filtration systems to capture sawdust and other fine particles. This keeps the workspace clean and reduces risks for workers. A cleaner environment also results in higher-quality finished products. This is crucial for maintaining customer satisfaction.

Textile manufacturing

Textile production involves – spinning, weaving, and dyeing processes that release lint, dust, and chemical fumes into the air. Without effective air filtration – these contaminants can cause respiratory issues for workers.

Filter sleeve holders ensure that filtration systems operate effectively in textile factories. They help capture airborne particles, keeping the environment safer for everyone involved.

Why these systems are important for industries?

Across all these industries – the need for clean air isn’t just about compliance—it’s about safety, efficiency, and sustainability. Filter sleeve cages and reliable air filtration systems are the unsung heroes of industrial processes. They protect workers, improve product quality, and help industries meet environmental standards.

If you are part of any of these industries – investing in high-quality filter sleeve holders and cages isn’t optional—it’s essential. They are the foundation of efficient air filtration systems – making them a worthwhile investment for any operation.

Would you like to explore more about these components or how they can improve air quality in your facility? Let me know—I’d be happy to get deeper into this topic.